Pavers for driveway installations offer homeowners a powerful upgrade over traditional concrete or asphalt surfaces. If you’re shopping for driveway pavers, here are the main types to consider:

Top Driveway Paver Options:

Your driveway is the first thing visitors see when they arrive at your home. It’s not just a place to park your car—it’s a major part of your home’s curb appeal and value. According to research from Thumbtack, homeowners perceive a house with high curb appeal to be 34% more valuable than the same house with poor curb appeal.

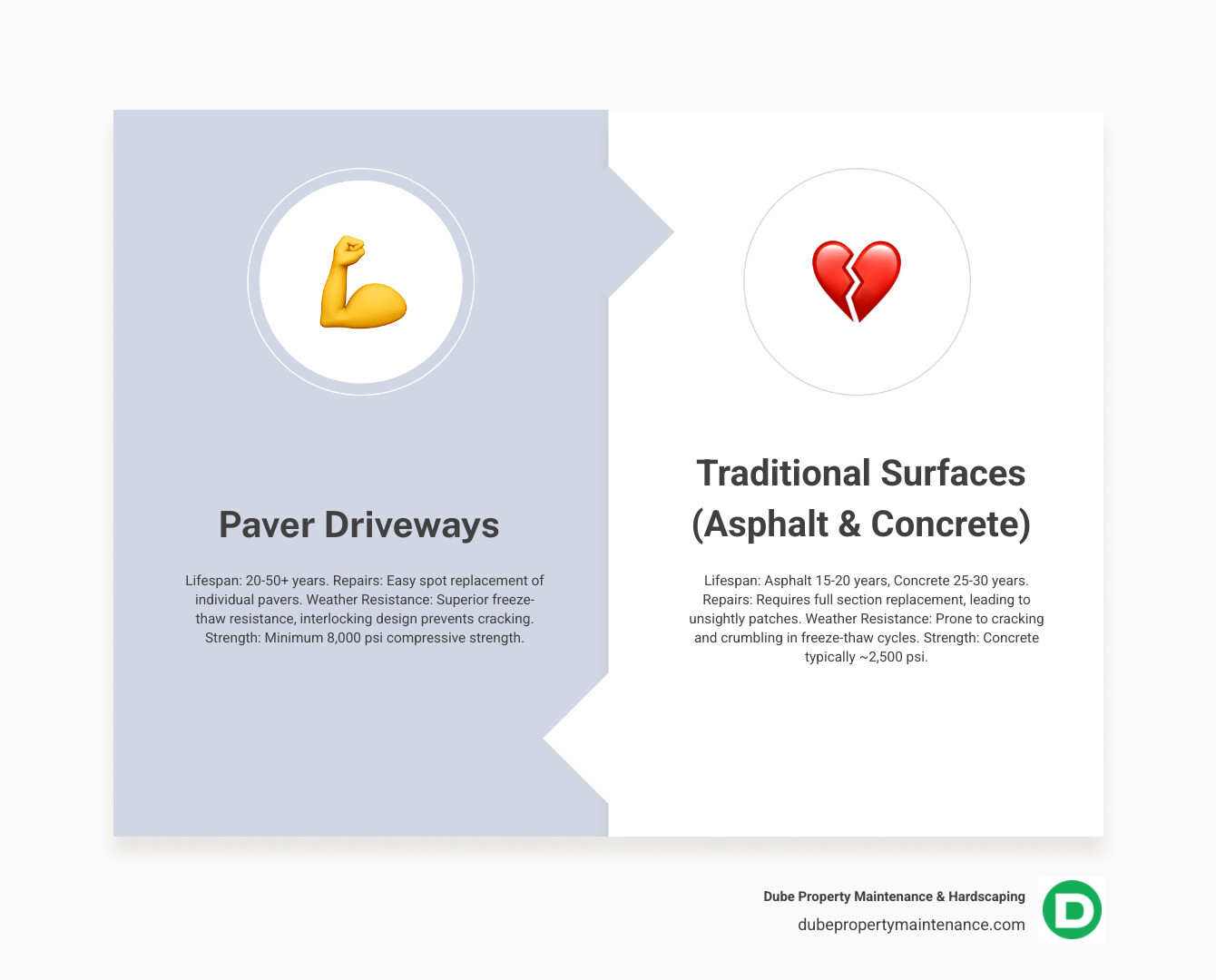

Unlike traditional poured concrete that cracks under pressure or asphalt that crumbles in extreme temperatures, pavers offer superior strength and flexibility. They’re rated at a minimum of 8,000 psi compressive strength—more than twice as strong as typical concrete driveways. Their interlocking design allows for natural expansion and contraction without cracking, making them ideal for the freeze-thaw cycles common in Massachusetts and New Hampshire.

Paver driveways typically last 20 to 30 years with minimal maintenance, and often 50 years or more with proper care. When damage does occur, you can simply replace individual pavers rather than tearing up and repaving entire sections—a huge advantage over concrete or asphalt.

Whether you’re drawn to the design flexibility of concrete pavers, the natural beauty of stone, or the environmental benefits of permeable options, choosing the right pavers for your driveway is an investment in both function and style.

Pavers for driveway word roundup:

When considering pavers for driveway applications, one of the most compelling advantages is their inherent strength and flexibility. Unlike a monolithic slab of poured concrete, which is prone to cracking due to ground movement or harsh weather, paver driveways are constructed using an interlocking system. This system allows for natural expansion and contraction, effectively preventing the unsightly cracks often seen in traditional concrete or asphalt.

Concrete pavers, for instance, are manufactured to be incredibly durable. According to ASTM guidelines, they must meet a minimum compressive strength of 8,000 psi (pounds per square inch). This is significantly stronger than the 2,500 psi typically found in poured concrete driveways. Our pavers at Dube Property Maintenance & Hardscaping often exceed these standards, ensuring a robust surface that can withstand the weight of vehicles, even heavy traffic.

The strength of an interlocking paver system comes not just from the individual pavers, but from their collective action. The combined effect of the paver shape, tight joint spacing, carefully prepared base, and specific laying patterns (like herringbone) helps distribute loads across a wider area. This load distribution is key to their durability and ability to resist movement and cracking, especially during the intense freeze-thaw cycles we experience in Massachusetts and New Hampshire. This robust design means a longer-lasting, more resilient driveway for your home. For more detailed information on how these systems work, you can explore our resources on interlocking concrete pavers.

Investing in pavers for driveway projects is not just about initial aesthetics; it’s a smart long-term financial decision. While the upfront cost of a paver driveway might sometimes be higher than poured concrete or asphalt, the life cycle cost over several decades often proves to be less. This is because pavers are remarkably durable and require minimal maintenance, significantly reducing expenses over their lifespan.

A key advantage of paver driveways is the ease of repair. If a section of your driveway is damaged—perhaps by a heavy impact, a stubborn oil stain, or shifting ground—individual pavers can be easily lifted and replaced. This means no unsightly patches or the need to tear up and repave entire sections, which is often the case with asphalt or concrete. The ability to perform spot repairs seamlessly maintains the aesthetic integrity of your driveway and saves you considerable time and money in the long run.

With proper care, a paver driveway can last 20 to 30 years, and often 50 years or more. This longevity, combined with simple, cost-effective repairs, makes pavers a superior choice for homeowners seeking lasting value. To learn more about keeping your paver driveway in top condition, visit our guide on paver driveway maintenance.

Choosing the right material for your pavers for driveway project involves balancing aesthetics with functionality, and of course, considering our unique climate in Massachusetts and New Hampshire. We want a driveway that not only looks fantastic but also stands up to heavy use, snow, ice, and fluctuating temperatures for decades.

Here’s a comparison of the top paver types suitable for driveways:

| Feature | Concrete Pavers | Natural Stone Pavers |

|---|---|---|

| Durability | Very high; engineered for strength (8,000+ psi) | High; naturally strong, resists wear |

| Style Options | Unlimited colors, shapes, textures; highly versatile | Unique, organic look; varied colors and textures |

| Maintenance | Low; occasional cleaning, joint sand replenishment | Low; occasional cleaning, sealing may be recommended |

| Average Cost | Moderate to High (due to installation complexity) | High (due to material cost and installation complexity) |

When it comes to pavers for driveway applications, concrete pavers stand out as the most popular and versatile option. Their manufacturing process allows for an incredible range of design possibilities, offering you the freedom to create a custom look that perfectly complements your home’s architecture and landscape.

Concrete pavers offer the most design flexibility because they are manufactured in a variety of colors, sizes, and textures. Whether you envision a sleek, modern driveway with large format pavers or a more traditional, cobble-stone aesthetic, concrete pavers can bring your vision to life. This versatility means we can mix and match colors, shapes, and textures to create intricate patterns and unique designs.

Beyond aesthetics, these pavers are engineered for strength. They are typically twice as strong as poured concrete, and their interlocking design ensures they can handle the weight of vehicles, resisting cracking even with heavy use. This makes them a cost-effective choice in the long run, as their durability translates to fewer repairs and a longer lifespan. For a deeper dive into selecting the perfect options, explore our guide on choosing the perfect pavers materials and styles.

As environmental awareness grows, so does the demand for sustainable hardscaping solutions. Permeable pavers for driveway installations offer a fantastic eco-friendly alternative to traditional impervious surfaces like asphalt and poured concrete. These innovative pavers are designed to manage stormwater directly on-site, reducing runoff and promoting groundwater recharge.

Many communities, including those in Massachusetts and New Hampshire, have limitations on the amount of impervious surface area allowed on a property. Permeable pavers can help overcome these limitations, potentially allowing for a wider driveway or more extensive paved areas than would otherwise be possible.

How do they work? Permeable pavers are installed with wider gaps between each unit, which are then filled with small, angular aggregate (like gravel) rather than traditional sand. This allows rainwater to filter through the surface, into a specially designed open-graded base, and then slowly seep into the ground below. Some permeable pavers, like Turfstone, even have open cells where grass or other vegetation can grow, creating a green and functional surface. Turfstone pavers, for example, not only preserve a natural, eco-friendly environment but also support up to 5,000 pounds per square inch, making them suitable for vehicles while allowing water to pass through.

Here are some key benefits of permeable pavers:

For homeowners in our service areas looking to improve their property’s sustainability and manage water more effectively, permeable pavers for driveway applications are an excellent choice. Find more about these innovative options on our permeable driveway page.

Your driveway is more than just a functional path; it’s an integral part of your home’s exterior design. With pavers for driveway projects, you have an unparalleled opportunity to improve your home’s curb appeal while ensuring lasting durability.

We can help you create a stunning entrance that complements your home’s architectural style, from classic colonial to modern contemporary. The flexibility of pavers allows for intricate patterns, decorative borders, and accents that truly make a statement. Imagine a circular driveway that not only improves vehicle safety but also creates a grand entrance, or subtle paver lighting that adds a welcoming ambiance at night.

Selecting the perfect pavers for driveway applications involves a thoughtful consideration of several factors:

When selecting pavers for driveway applications, especially for areas with heavy vehicle traffic, a crucial technical consideration is the paver’s aspect ratio. This might sound like a detail only an engineer would care about, but it directly impacts the structural integrity and longevity of your driveway.

The aspect ratio refers to the paver’s length divided by its thickness. For driveways, where pavers will endure significant vehicular loads, the Concrete Masonry and Hardscapes Association (CMHA) provides important guidelines. Their recommendations state that pavers used for driveways should not have an aspect ratio greater than 4:1.

Why is this important? Pavers with a high aspect ratio (meaning they are much longer than they are thick) are more susceptible to rocking, shifting, or even breaking under the concentrated weight and dynamic forces of vehicle tires. A lower aspect ratio, such as 4:1 or less, ensures that the paver has sufficient thickness relative to its length to remain stable and distribute loads effectively across the bedding layer and base. This helps prevent paver failure, maintains the interlock between units, and contributes to a durable, long-lasting driveway that can withstand years of use in our Massachusetts and New Hampshire communities. Always ensure your chosen pavers meet these industry standards for optimal performance.

A beautiful and durable paver driveway is a result of not only high-quality materials but also expert installation. While some DIY enthusiasts might consider tackling smaller paver projects, for a driveway that will endure heavy vehicle traffic and harsh weather, professional installation is paramount. Our team at Dube Property Maintenance & Hardscaping has the experience and equipment to ensure every step of the process is executed flawlessly.

Professional installation ensures proper base preparation, correct paver laying techniques, and adherence to drainage requirements. This is especially crucial for driveways that experience heavy vehicle traffic, where the base needs to be extra robust. We can also integrate modern conveniences, such as compatibility with heated driveway systems, to make winter snow removal a breeze in our New England climate. To understand the comprehensive process involved in creating a resilient paver driveway, dig into our guide on how to install a paver driveway.

The foundation of any successful paver driveway lies in its base preparation. This is perhaps the most critical step, as a poorly prepared base can lead to settling, shifting, and ultimately, a failing driveway.

Our process begins with careful excavation to the appropriate depth, taking into account the thickness of the pavers, bedding sand, and the substantial compacted gravel base required for vehicular traffic. For driveways, we recommend an 8-inch depth of crushed stone base to ensure maximum support.

Next, we often use geotextile fabric. This fabric, made of plastic threads, allows water to pass through but prevents fine soil particles from mixing with the aggregate base. This separation is vital, especially over silt and clay soils common in our region, as it keeps the base clean and prevents it from weakening over time.

A crucial layer is the compacted gravel base. This is typically made of crushed stone (1 inch down to dust) and is installed in layers, each compacted thoroughly. This provides a stable, load-bearing platform. On top of this, a uniform sand setting bed is carefully screeded. We use concrete sand, as most limestone screenings or stone dust contain too many fine particles that can slow drainage and rut under repeated loads.

Proper drainage is non-negotiable. We ensure the driveway is constructed with a minimum slope of 1.5% (about 3/16 inch per foot) away from any structures, often aiming for 2% (1/4 inch per foot) for even better water shedding. Finally, robust edge restraints are installed around the perimeter. These restraints provide essential lateral resistance, keeping the pavers tightly interlocked and preventing them from spreading or shifting under traffic or freeze-thaw cycles. Understanding the specifics of this critical layer can be found on our page dedicated to the base for pavers.

Once your beautiful paver driveway is installed, a little routine care goes a long way in preserving its appearance and extending its lifespan. Pavers for driveway projects are known for their low maintenance, but consistent upkeep ensures they remain a stunning asset to your home.

Routine cleaning involves sweeping away debris and occasional washing with a hose. To combat weed growth between joints, we recommend using high-quality joint sand stabilizers, often referred to as polymeric sand. This specially formulated sand hardens when moistened, locking the pavers in place, minimizing weed intrusion, and preventing sand washout.

While not strictly required, sealing your paver driveway is highly recommended, especially in areas like Massachusetts and New Hampshire where driveways are exposed to harsh elements. Sealing offers several key benefits:

We advise using a breathable, penetrating sealer, and always testing a small, inconspicuous area first. Sealing is typically done every 2-5 years, depending on the product and traffic. For a comprehensive understanding of this process and its associated costs, refer to our detailed information on the cost to seal driveway pavers.

We often hear common questions from homeowners considering pavers for driveway installations. Here are some of the most frequent inquiries and our expert answers.

With proper installation and routine maintenance, a paver driveway is an incredibly long-lasting investment. Paver driveways typically last 20 to 30 years with minimal maintenance, and with diligent care, they can often endure for 50 years or more. This exceptional longevity is largely due to their interlocking design, which allows for slight movement. This flexibility prevents the cracking and damage that often plague rigid surfaces like poured concrete, especially when subjected to ground shifts and our region’s freeze-thaw cycles.

Absolutely, pavers for driveway applications are well-suited for sloped areas. The key to a successful installation on a slope lies in meticulous base preparation, the use of strong edge restraints, and selecting appropriate interlocking patterns. Patterns like herringbone are particularly effective on slopes because they provide superior interlock and load distribution, resisting the downward forces of gravity and vehicular traffic.

It’s important to be aware that local building codes in Massachusetts and New Hampshire may specify maximum grade requirements for driveways, often around 15%. While paver streets have been constructed on grades as steep as 18%, we always recommend consulting with local regulations and having a professional assessment to ensure your driveway’s slope is safe and compliant. Our team can help you steer these requirements and design a durable solution for your sloped property.

While sealing your paver driveway is not strictly required for its structural integrity, we highly recommend it for several practical and aesthetic benefits. A good quality sealer acts as a protective layer, making your driveway more resistant to:

Furthermore, sealing can improve the pavers’ natural colors, giving them a richer, more vibrant appearance. We always recommend using a breathable, penetrating sealer and following the manufacturer’s instructions, including testing in an inconspicuous area first. This small extra step can significantly preserve the beauty and ease of maintenance of your pavers for driveway for years to come.

Choosing pavers for driveway installation is a decision that lifts your home’s exterior with a foundation of style, durability, and long-term value. From the exceptional strength and flexibility of interlocking concrete pavers to the environmental benefits of permeable options, a paver driveway offers a superior solution compared to traditional asphalt or poured concrete. You gain design flexibility, easy maintenance, and a significant boost to your home’s curb appeal.

At Dube Property Maintenance & Hardscaping, we are experts in delivering high-quality, comprehensive outdoor solutions. Our professional team brings years of experience to every project, ensuring meticulous installation and lasting results. We are proud to serve homeowners and businesses across Massachusetts, including Andover, Methuen, North Andover, and many other towns, as well as Salem, NH, and surrounding communities.

Ready to invest in a beautiful and resilient driveway that will stand the test of time? A paver driveway is a smart investment that pays dividends in both aesthetics and functionality.

Get an estimate for your hardscape construction service today and let us help you transform your driveway into a stunning entrance.