The choice between woven vs non woven geotextile is a critical decision that impacts the long-term success of any hardscaping project. The wrong fabric can lead to a sinking driveway, a clogged drainage system, or a failed retaining wall. Understanding the fundamental differences is key.

Quick Answer: The Core Differences

| Factor | Woven Geotextile | Non-Woven Geotextile |

|---|---|---|

| Primary Function | Reinforcement & Stabilization | Filtration & Drainage |

| Strength | High tensile strength | Reliable but more flexible |

| Elongation | 5-25% (minimal stretch) | 50%+ (very flexible) |

| Water Flow | Low permeability | High permeability |

| Best For | Roads, driveways, parking lots | French drains, retaining walls, erosion control |

As one landscape professional put it: “Choosing the right geotextile isn’t just a box to tick. It can have a significant impact on how your project performs over time.”

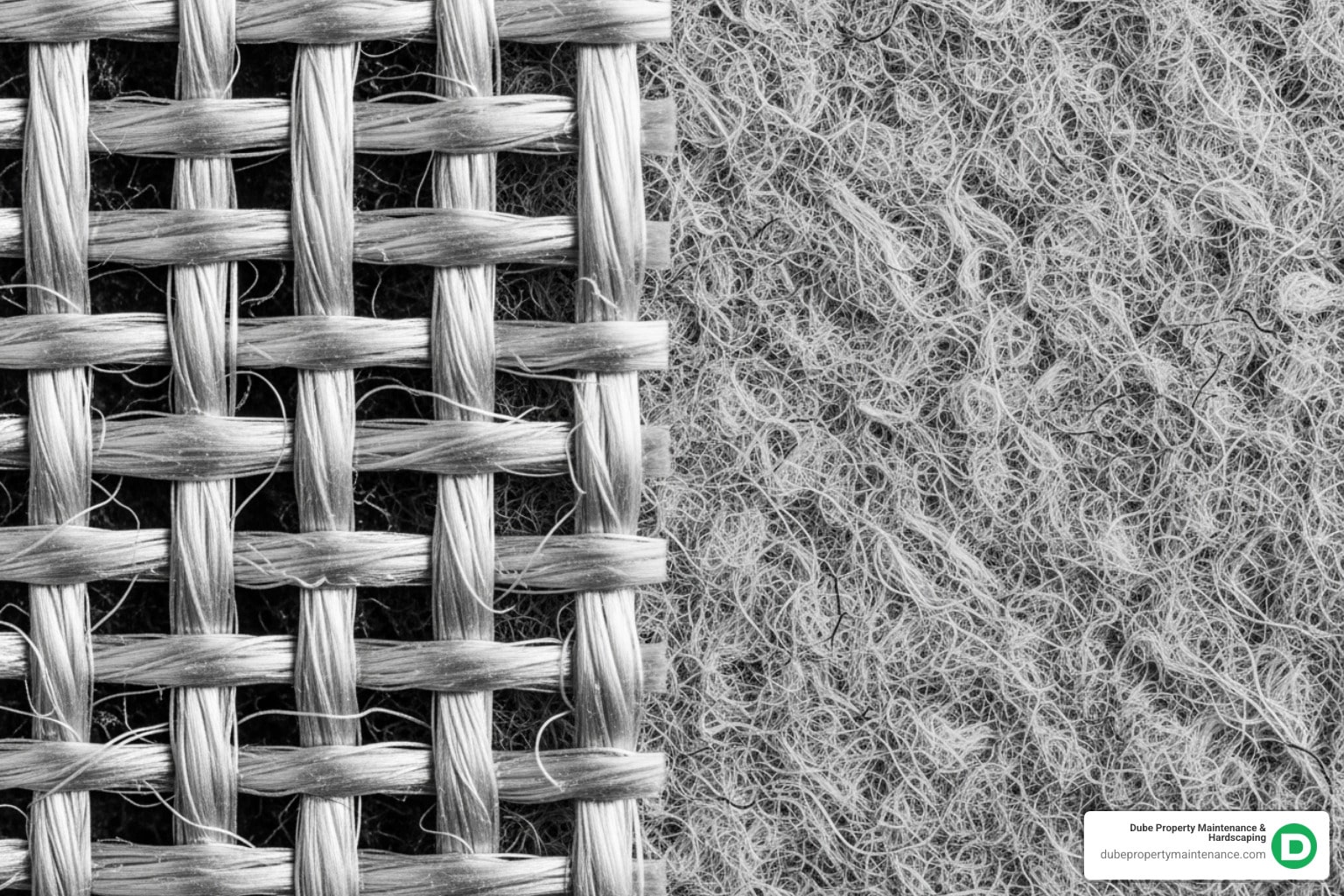

The decision boils down to your project’s primary need. Woven fabrics provide reinforcement, acting like rebar in concrete. They are woven from polypropylene fibers into a tight pattern, giving them the strength to handle heavy loads and separate soil layers.

Non-woven fabrics are specialized filters. Made by needle-punching fibers into a felt-like mat, they allow water to pass through freely while blocking soil particles, making them essential for drainage.

While they may look similar, their functions are distinct. Using a woven fabric for drainage is like using a waterproof tarp as a coffee filter—it simply won’t work. For homeowners in Methuen and surrounding areas, our harsh New England weather puts extra stress on hardscapes, making the right geotextile choice crucial for a lasting investment.

Woven vs non woven geotextile glossary:

Think of woven geotextiles as the powerlifters of the fabric world. When your project needs serious muscle to handle heavy loads and keep soil layers from shifting, this is the fabric that gets the job done.

These fabrics are strong by design. They are manufactured by weaving individual polypropylene threads, often as flat slit films or interlocking fibrillated yarn, into a tight, grid-like pattern. This weaving process creates a fabric with impressive high tensile strength and low elongation, meaning it resists stretching under tension. This rigidity is exactly what makes woven fabrics excel at load distribution.

The tight structure also provides excellent puncture resistance and durability, making them ideal for soil stabilization. This is often called basal reinforcement geotextile, a term for creating a rock-solid base layer. When comparing woven vs non woven geotextile options, the woven type is the clear winner when strength is the top priority.

Woven geotextiles excel at reinforcement and separation. They prevent different soil layers from mixing, which is crucial for any project supporting significant weight.

The trade-off for this strength is low permeability. Water does not flow through the tight weave easily. While this is acceptable for reinforcement projects, it makes woven fabrics unsuitable for applications where drainage is the primary goal.

The durability of this geo fabric cloth ensures it functions for decades, making it a sound investment. At Dube Property Maintenance & Hardscaping, we use woven fabrics whenever the main challenge is bearing weight and preventing soil movement.

While woven geotextiles provide strength, non-woven geotextiles are the drainage specialists, expertly managing water flow while keeping soil in place.

Instead of weaving, non-woven geotextiles are made by needle-punching a mat of synthetic fibers (polyester or polypropylene) until they interlock into a cohesive fabric. The result is a material with a felt-like texture and a random internal structure.

This random fiber orientation creates a maze of tiny passages, giving the fabric two key properties: high permeability, which allows water to flow through freely, and high elongation (stretching 50% or more), which allows it to conform to irregular surfaces without tearing.

Non-woven geotextiles are categorized by fabric weight, measured in ounces per square yard (e.g., 8oz). A higher weight indicates a thicker, more robust fabric with greater puncture resistance and durability. The right weight depends on the project’s demands.

Non-woven geotextiles are essential for projects requiring filtration and drainage. Their porous structure allows water to pass while holding back soil particles, preventing clogs.

In the woven vs non woven geotextile debate, if your project’s success hinges on efficient water movement, non-woven is almost always the correct choice.

Choosing between woven vs non woven geotextile is like picking the right tool for the job. Both are effective, but for entirely different tasks. Using the wrong one can lead to costly consequences.

Let’s break down how these two fabrics stack up:

| Factor | Woven Geotextile | Non-Woven Geotextile |

|---|---|---|

| Manufacturing Method | Weaving individual synthetic yarns (polypropylene, polyester) in a uniform, crisscross pattern. | Bonding random synthetic fibers (polypropylene, polyester) via needle-punching, thermal, or chemical processes. |

| Primary Function | Reinforcement, Stabilization, Separation (heavy-duty) | Filtration, Drainage, Separation (permeable), Cushioning |

| Tensile Strength | High (e.g., 80 kN/m or higher for specialized types) | Reliable, but generally lower than heavy-duty wovens for the same weight; strength varies with weight. |

| Elongation (%) | 5-25% (minimal stretch, rigid) | 50%+ (very flexible, high stretch) |

| Permeability/Flow Rate | Low, semi-impermeable (tight weave restricts water flow) | High (porous, felt-like structure allows free water flow) |

| Puncture Resistance | Excellent due to tight weave and high strength. | Good to Excellent, especially with higher weights. |

| Durability | Very high, long-term structural integrity. | Good, but can break down faster than wovens in some conditions. |

| Best For | Roads, driveways, parking lots, retaining wall foundations, heavy load-bearing areas. | French drains, retaining wall backfill, subsurface drainage, erosion control, geomembrane protection, low-load pathways. |

The physical properties of woven vs non woven geotextile determine their real-world applications. Woven fabric’s high tensile strength and low elongation (rigidity) make it best for reinforcement under heavy loads, like driveways. It holds its shape and distributes weight effectively.

Non-woven fabric’s high elongation makes it incredibly flexible, allowing it to conform to uneven surfaces without tearing. This flexibility is a major advantage in applications requiring adaptability.

Permeability is the most critical distinction. Non-woven geotextiles have a high flow rate, making them superstars for drainage. Woven geotextiles have low permeability by design, making them ideal for separation and reinforcement but unsuitable for drainage.

Both types offer excellent durability and puncture resistance for their intended applications. While woven fabrics excel in long-term structural integrity, heavier-grade non-wovens provide superior cushioning and puncture protection due to their thickness.

This is where the woven vs non woven geotextile choice becomes crystal clear. Non-woven geotextiles are engineered for filtration and drainage. Their porous, felt-like structure allows water to pass through quickly while trapping fine soil particles, preventing clogs in drainage systems. This is measured by permittivity (flow rate) and Apparent Opening Size (AOS), which indicates its filtering capability.

For French drains or drainage behind retaining walls, non-woven fabric is non-negotiable. It keeps water moving and prevents silt buildup that would cause the system to fail. Our guide on Geotextile Fabric Retaining Wall installations shows this in practice.

Woven geotextiles, with their low permeability, are not designed for drainage. Using one in a French drain would restrict water flow, leading to pressure buildup and system failure. The rule is simple: if water needs to move through it, choose non-woven. If you need to stabilize soil under a heavy load, choose woven.

Choosing the right geotextile isn’t about guessing; it’s about matching the fabric’s properties to your project’s specific needs. We’ve seen too many projects fail because the wrong material was used. When evaluating a site in Methuen or surrounding areas, we consider soil conditions, the water table, and load-bearing requirements to make an informed decision.

Think of it this way: you wouldn’t use a filter to hold up a building, and you wouldn’t use a steel beam to purify water. The choice between woven vs non woven geotextile follows the same logic. Here’s a practical guide for common applications.

Driveways, Roads, and Parking Lots

Retaining Walls

Patios and Walkways

French Drains and Drainage Systems

Shoreline and Erosion Control

For specific advice on a dry stack retaining wall, see our guide on if you need filter fabric for dry stack retaining wall. The best choice always depends on your site, and that’s where professional evaluation makes a difference.

We often discuss the finer points of woven vs non woven geotextile with clients. Here are answers to some of the most common questions, which can help clear up misconceptions and prevent costly project mistakes.

No. A French drain’s job is to collect and move water quickly. Woven geotextiles have low permeability, meaning they restrict water flow. Using one would be like trying to drain pasta through a canvas bag—water would back up, creating the hydrostatic pressure you’re trying to prevent. The tight pores of woven fabric also clog more easily with fine soil.

Non-woven geotextiles are purpose-built for drainage. Their felt-like structure allows water to pass through rapidly while filtering out silt. For any drainage system, non-woven is the only correct choice. Our Filter Fabric for French Drain guide shows the proper installation.

They are strong in different ways, and the “stronger” choice depends on the job.

If your project needs to bear heavy loads without deforming, woven fabric’s tensile strength is superior. If it needs to protect a liner or adapt to ground movement, a thick non-woven’s flexibility and puncture resistance is the stronger choice.

Those numbers refer to the fabric’s weight per square yard. It’s a simple way to gauge its robustness. An 8oz non-woven fabric is thicker and denser than a 4oz version, containing twice the material.

This weight directly correlates to performance. A heavier fabric offers:

While modern tests are more precise, weight remains a reliable historical specification for quality. For most residential drainage projects in the Methuen area, an 8oz non-woven fabric provides an excellent balance of performance and cost. More demanding jobs may require a 10oz or heavier fabric.

The bottom line on woven vs non woven geotextile is simple: match the tool to the job. Woven fabrics are for strength and reinforcement; non-woven fabrics are for filtration and drainage. Getting this choice right is not a minor detail—it’s fundamental to the longevity of your project, especially given the demanding New England climate.

A sinking driveway or a failed drainage system are costly problems that proper material selection can prevent. The right fabric is an insurance policy for your investment, protecting it from the ground up.

At Dube Property Maintenance & Hardscaping, we’ve built our reputation on understanding these details. Our team applies this knowledge to your specific site conditions in Methuen and our surrounding service areas, considering soil type, drainage patterns, and project goals to ensure a flawless result. We believe in building projects that last by using quality materials installed correctly the first time.

Ready to start your next hardscaping project with confidence? Explore our retaining wall services to see how we can transform your outdoor space, or reach out to our team directly. We’ll guide you through your options and ensure your project is built to stand the test of time.