A geotextile bag retaining wall is a flexible, eco-friendly alternative to traditional concrete or stone walls that uses soil-filled fabric bags to create stable, vegetated structures. These innovative systems combine the strength of mechanically stabilized earth with the beauty of living walls.

Key features of geotextile bag retaining walls:

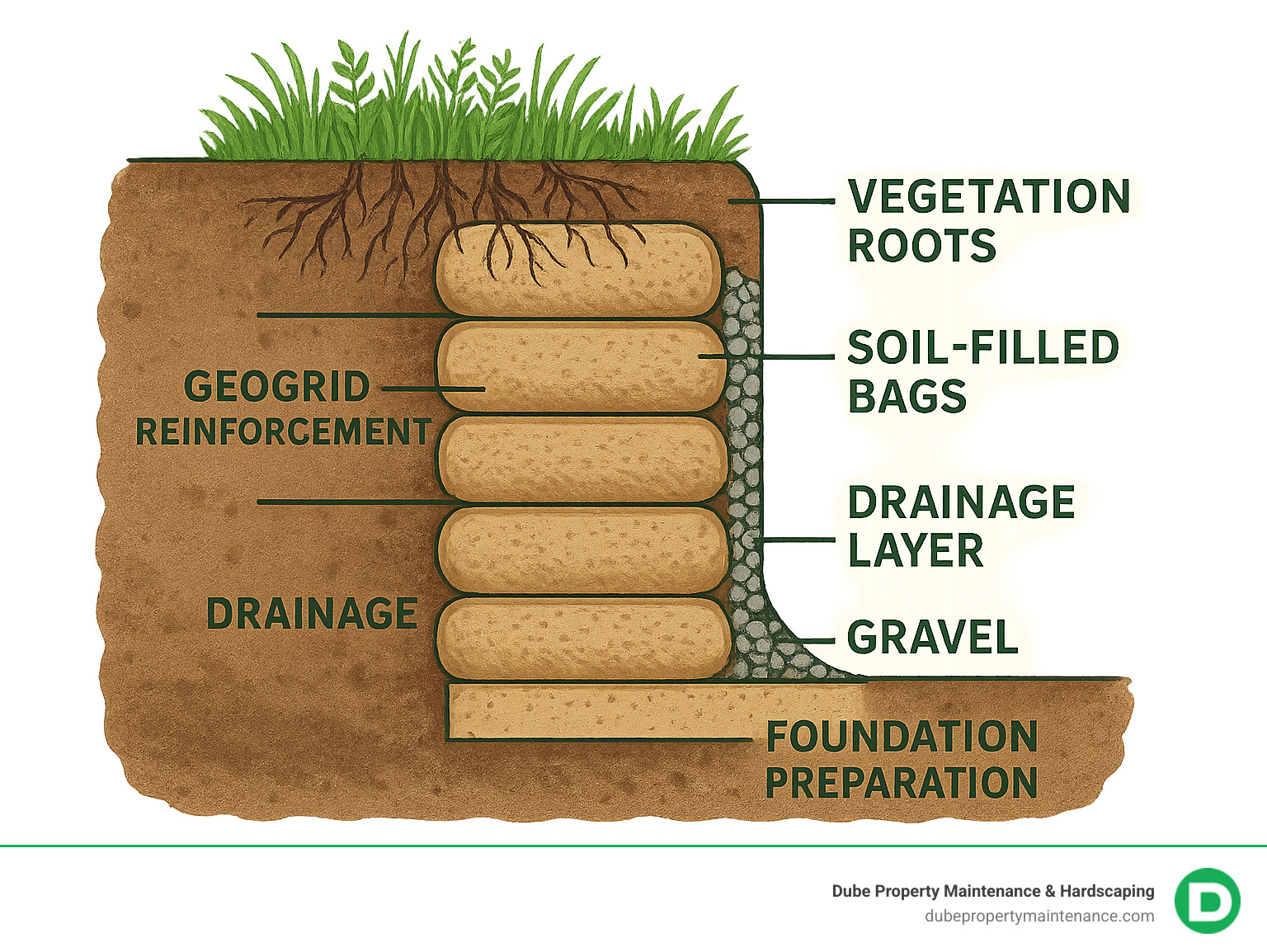

These systems work by encapsulating engineered soil mix in non-woven geotextile bags, which are then stacked and interlocked to form retaining structures. As vegetation establishes, roots grow through the bags into the native soil, creating a self-reinforcing system that gets stronger over time.

The technology has proven successful in major projects, including the Fields Ranch East golf course in Texas, where nearly 2,000 linear feet of geotextile bag walls were built up to 20 feet high. For homeowners in Methuen and surrounding areas dealing with slope erosion or drainage issues, these systems offer functionality and natural beauty.

Unlike rigid concrete walls that can crack under freeze-thaw cycles common in Massachusetts, geotextile bag walls move with seasonal ground changes while maintaining structural integrity.

A geotextile bag retaining wall uses specially designed fabric bags filled with soil to create sturdy retaining structures that actually get prettier over time. Unlike rigid concrete walls, these systems use mechanically stabilized earth (MSE) – working with the ground instead of fighting against it.

Each bag is made from high-tech synthetic materials like polypropylene, filled with carefully engineered soil mix, then stacked like oversized building blocks. These flexible systems can bend and flex with seasonal ground movement – something every homeowner in Massachusetts knows well.

What sets these walls apart is their ability to become living, breathing structures. As vegetation takes root through the permeable bags, you’re creating a thriving ecosystem that actually strengthens over time.

The magic behind geotextile bag retaining walls combines physics with modern engineering. Each soil-filled bag uses its own mass to resist pressure from the earth behind it. But unlike traditional gravity walls that rely purely on brute force, these systems are much more sophisticated.

Gravity does the heavy lifting – the weight of each bag provides primary resistance against lateral earth pressure. Because the bags can flex and adjust to ground movement, they won’t crack like concrete when the ground freezes and thaws.

The reinforcement component is where things get clever. The geotextile fabric provides tensile strength, working like a flexible container. When you add optional geogrid layers wrapped around bag courses, you’re extending reinforcement deep into the backfill zone, creating a “reinforced soil mass.”

Interlocking keeps everything honest. Modern systems use plastic gripper plates or connection pins to mechanically link each layer of bags. This prevents individual bags from shifting while maintaining overall flexibility.

The real game-changer is root binding. As plants establish themselves, their roots penetrate through the permeable bags and create natural reinforcement. Research shows this biological reinforcement significantly boosts long-term stability.

The non-woven geotextile bags are made from needle-punched polypropylene or polyester designed to let water and roots pass through while keeping soil contained. These engineered bags resist UV rays, acids, alkalis, and biological attack, with warranties often exceeding 15 years.

The engineered fill material is typically 60% sand and 40% topsoil, carefully balanced to promote rapid vegetation while providing structural stability. Some systems use lightweight aggregates or recycled materials to reduce weight and environmental impact.

For taller walls over 4 feet, geogrid reinforcement gets wrapped around bag courses and extended into the backfill zone. This certified geogrid can enable slopes up to 70° with a 120-year design life.

Connection plates made from plastic or metal interlock the bag layers, creating mechanical connection without rigid bonding. Finally, drainage systems take advantage of the bags’ natural permeability, with water filtering through naturally.

Proper design is critical for successful geotextile bag retaining wall installation. While these systems are more forgiving than rigid walls, they still require careful engineering analysis, especially for heights over 4 feet.

Soil Analysis: Understanding existing soil conditions is fundamental. The system works best with free-draining soils, though it can accommodate various conditions better than rigid walls. Expansive clay soils are actually well-suited to flexible bag systems.

Wall Height Limits: While geotextile bag retaining walls can reach heights of 10 meters (over 30 feet), practical limits depend on site conditions, reinforcement design, and local building codes. Most residential applications range from 3-8 feet.

Slope Angle Considerations: The wall face can be constructed at various angles from vertical to 70° slopes, depending on reinforcement design. Steeper faces require more engineering but offer space-saving advantages.

Factor of Safety: Design calculations should incorporate safety factors of 1.5-1.75 for fabric tensile strength and pullout resistance.

Scientific research on geotextile soil wall reinforcement provides detailed engineering guidance for professional applications.

The success of any geotextile bag retaining wall depends heavily on proper fill material selection. The ideal mix balances structural requirements with vegetation needs.

Sand-Topsoil Mix: The most common approach uses 60% sand and 40% topsoil. Sand provides drainage and structural stability, while topsoil supplies nutrients for plant growth. This combination typically weighs 25-30 kg per bag when properly filled.

Lightweight Aggregates: For applications where weight is a concern, lightweight aggregates like expanded shale can reduce bag weight while maintaining stability and improving drainage.

Recycled Soils: Many installations use on-site material or imported soil, aggregate, and compost blends. This reduces transportation costs and environmental impact while improving soil biology.

For walls over 4 feet high or in challenging conditions, reinforcement and drainage become critical design elements.

Geogrid Length: When geogrid reinforcement is used, the length must be calculated based on soil loads and pullout resistance. As a rule of thumb, geogrid should extend at least 0.7 times the wall height into the backfill zone.

Embedment Depth: Geogrid layers should be embedded at least 3 feet into the backfill, with proper overlap between adjacent sheets.

Weep Lines: While the bags themselves are permeable, formal drainage systems may be needed for high-flow situations. Perforated pipes can be installed behind the wall at regular intervals.

More info about retaining wall drainage provides additional guidance on proper drainage design.

MSE systems using certified geogrid can achieve a 120-year design life for reinforced retaining structures, far exceeding many traditional alternatives.

UV Resistance: Modern geotextile materials resist UV degradation, with typical warranties exceeding 15 years. Once vegetation establishes, the living canopy provides additional UV protection.

Chemical Stability: The synthetic materials resist acids, alkalis, and biological degradation, making them suitable for a wide range of conditions.

Biological Improvement: Unlike traditional materials that degrade over time, geotextile bag walls actually improve with age as vegetation establishes and root systems develop.

Building a geotextile bag retaining wall is manageable once you understand the process. Think of it like building with oversized LEGO blocks – each piece has its place, and the system is designed to work together naturally.

The beauty of this approach is that it doesn’t require specialized masonry skills or heavy equipment. A motivated homeowner can tackle smaller walls (under 4 feet), while larger projects benefit from professional installation.

The foundation of any successful geotextile bag retaining wall starts with properly prepared materials and careful bag filling.

Getting the site ready involves clearing vegetation and excavating a shallow trench for your first row of bags. This trench doesn’t need to be deep – just 6 to 12 inches is plenty.

Mixing your fill material requires that 60% sand and 40% topsoil blend to feel just right – slightly moist but not muddy. If you squeeze a handful and it holds together but crumbles when you poke it, you’ve got the perfect consistency.

The actual filling process works best with a simple funnel or filling frame. Fill each bag to about 90% capacity – this gives you room to shape and compact them without making them too heavy to handle. Each filled bag should weigh those standard 25-30 kg (55-66 pounds).

Quality control matters here. Every bag should feel similar in weight and shape. Inconsistent filling leads to uneven settlement down the road.

This is where you really see the geotextile bag retaining wall system come to life. The stacking process transforms individual bags into a cohesive structural system.

Start with that first course by placing bags in your prepared trench, making sure they’re level and properly aligned. Use a hand tamper or plate compactor to achieve uniform density.

Installing gripper plates between each course creates the mechanical connection that keeps your wall acting as one unit. These plastic plates prevent individual bags from shifting while maintaining flexibility.

Staggering your seams works just like laying bricks – you want a running bond pattern where the joints don’t line up vertically. This distributes loads more evenly throughout the wall.

Building in 8-inch lifts means compacting each course before placing the next one. This technique ensures proper density and interlocking between layers.

Adding geogrid reinforcement for taller walls involves wrapping the grid material around alternate bag courses and extending it back into the backfill zone.

Here’s where geotextile bag retaining walls truly shine compared to traditional walls. The living component doesn’t just look good – it actually makes the structure stronger over time.

Plant immediately after installation through hydroseeding, native plant plugs, or direct seeding. The permeable bags allow roots to penetrate right away.

Choose your plants wisely by selecting native species that thrive in your local conditions. Deep-rooted perennials provide the best structural reinforcement. In Massachusetts, native grasses and wildflowers work particularly well.

Root development happens quickly – research shows native plant roots begin penetrating the bags within just 15 days of planting. By day 100, you’ll have deep root systems providing significant structural reinforcement.

The ecological benefits are an added bonus that traditional walls simply can’t match. Your living wall creates habitat for beneficial insects and supports local wildlife.

When considering a geotextile bag retaining wall for your property, it’s important to understand how these systems perform in real-world conditions. The flexibility of these walls is perhaps their greatest strength. While concrete walls can crack under New England’s freeze-thaw cycles, geotextile bag walls simply flex and adjust.

Settlement tolerance is another game-changer. Traditional rigid walls can fail catastrophically if the foundation settles unevenly. Bag walls accommodate movement gracefully, settling along with the ground while maintaining structural integrity.

The biodiversity improvement these walls provide is remarkable. Instead of creating a sterile concrete barrier, you’re building habitat. Birds nest in the vegetation, beneficial insects find homes, and small wildlife use the living wall as a corridor through developed areas.

From an environmental standpoint, these systems deliver impressive results. The carbon footprint reduction of up to 50% compared to concrete walls comes from reduced material transport and manufacturing emissions.

The benefits of geotextile bag retaining walls become clear when you compare them with traditional options.

Installation speed is where these systems really shine. While a traditional stone or concrete wall might take weeks to complete, bag walls can be installed up to 5 times faster. This means less disruption to your property and lower labor costs.

Cost savings add up quickly. Lower material costs, reduced equipment needs, and faster installation translate to significant savings for homeowners.

The permeability of these systems solves problems that concrete walls actually create. Traditional walls block water flow, often leading to drainage issues and hydrostatic pressure buildup. Bag walls allow natural drainage while filtering runoff.

Aesthetic integration is perhaps the most obvious advantage. Instead of a harsh concrete barrier, you get a living wall that blends seamlessly with your landscape. Within a growing season, visitors often can’t tell where the wall ends and the natural slope begins.

Maintenance requirements actually decrease over time as vegetation establishes. While concrete walls may need periodic repairs, living walls get stronger and more attractive as they mature.

No system is perfect, and geotextile bag retaining walls do have some considerations worth discussing.

UV exposure during the establishment period is the primary concern. Before vegetation fills in, the bags are vulnerable to UV degradation. High-quality materials with UV stabilizers help, but the real solution is rapid plant establishment.

Vandalism concerns are real, especially in high-traffic areas. The soft surface can be damaged by foot traffic or intentional abuse. Strategic plant selection with thorny or dense species can discourage unwanted access.

Height limitations require careful consideration. While these systems can reach impressive heights with proper engineering, most DIY-friendly applications stay under 6 feet.

Permitting requirements can be tricky in some jurisdictions. Building officials unfamiliar with these systems may require additional engineering. Working with experienced contractors who understand local requirements can smooth the approval process.

The environmental benefits of geotextile bag retaining walls extend far beyond their reduced carbon footprint.

Stormwater management is dramatically improved compared to traditional walls. The permeable structure acts like a natural filter, removing pollutants and sediments from runoff while reducing peak flow rates.

Wildlife corridors created by living walls support local biodiversity in ways that concrete cannot. Small mammals, birds, and beneficial insects use these structures as habitat and travel routes through developed areas.

Air quality improvements come from the vegetation component, which filters pollutants and produces oxygen. The stormwater filtration capacity of these systems is particularly valuable in urban and suburban settings where runoff quality is a growing concern.

When considering a geotextile bag retaining wall for your property, understanding the investment and ongoing care helps you make the best decision for your landscape needs.

The cost picture for these systems varies dramatically based on project complexity and installation approach. For DIY enthusiasts, basic geotextile bag retaining wall kits typically range from $18-$50 per square foot, though premium systems with advanced reinforcement can reach $150+ per square foot. These are average costs based on internet data and not actual costs for Dube Property Maintenance & Hardscaping.

Professional installation naturally costs more but brings expertise and warranty protection. Contractor-installed systems generally range from $60-$180 per square foot, with complex projects requiring extensive engineering potentially reaching $540+ per square foot. The wide range reflects everything from simple residential slopes to sophisticated commercial applications.

What makes these systems particularly attractive is their long-term value. Unlike traditional walls that may need expensive repairs or replacement, geotextile bag walls actually improve with age as vegetation establishes. Annual maintenance typically involves basic vegetation management and inspection.

More info about building a retaining wall provides additional cost considerations and planning guidance.

Real-world applications demonstrate why property owners and contractors are choosing flexible wall systems over traditional alternatives.

The PGA Frisco Fields Ranch East golf course project showcases the technology’s capabilities on a grand scale. Nearly 2,000 linear feet of geotextile bag retaining walls were installed, with most structures reaching 10-15 feet high and one impressive wall climbing nearly 20 feet. The challenging aspect? Expansive clay soils that could shift up to six inches with moisture changes – conditions that would crack concrete walls but barely phase flexible bag systems.

A Wisconsin residential project used 1,500 individual units to create an extensive green retaining wall system. The homeowner addressed multiple slope stability issues across their property while creating an attractive landscape feature that blends seamlessly with natural surroundings.

Coastal applications have proven particularly successful, where the system’s flexibility accommodates wave action and tidal forces while the permeable design allows natural water movement.

What’s remarkable about these projects is their longevity. The PGA installation continues to perform flawlessly years after completion, with vegetation now fully established and providing additional structural reinforcement.

One of the biggest advantages of geotextile bag retaining walls is their low maintenance requirements. Unlike traditional walls that may need periodic repairs, these systems generally improve with age.

Annual inspection should be your primary maintenance activity. Walk the length of your wall looking for any damaged bags, unusual settlement, or drainage issues. Most property owners find this inspection takes less than an hour.

Vegetation management keeps your wall looking its best while maintaining structural integrity. Trim overgrown plants to maintain the desired appearance and prevent woody shrubs from potentially compromising bag integrity. This is typically needed 1-2 times per year.

Selective bag replacement is straightforward when needed. The modular design means you can replace individual damaged bags without affecting the entire structure.

Drainage maintenance involves flushing any formal drainage systems annually to prevent clogging. However, the naturally permeable bags usually handle water management without intervention.

The beauty of this maintenance approach is that most tasks can be handled by property owners themselves, reducing long-term costs while keeping the system performing at its best.

Permit requirements vary significantly by location and wall height. Generally, walls over 4 feet high require building permits and may need structural engineering plans. Some jurisdictions may be unfamiliar with geotextile bag systems, so working with experienced contractors who understand local requirements is valuable. We recommend checking with your local building department early in the planning process.

While geotextile bag retaining walls can theoretically reach heights of 10 meters (over 30 feet) with proper engineering and reinforcement, practical limits depend on several factors. Most residential DIY projects should stay under 4 feet to avoid permit requirements. Professional installations can safely reach 8-12 feet for most applications, with taller walls requiring sophisticated engineering analysis and reinforcement systems.

Smaller geotextile bag retaining walls (under 4 feet) are well-suited for DIY installation by capable homeowners. The bags typically weigh 45-55 pounds when filled, making them manageable for most people. However, proper technique is essential for long-term success. Larger walls, complex sites, or critical applications should involve professional contractors who understand the engineering requirements and local building codes.

Geotextile bag retaining walls are changing the game for property owners who want something better than boring concrete blocks or expensive stone walls. These living systems give you the strength you need with the natural beauty you want – and they actually get better with time as the plants grow and strengthen the structure.

If you’re dealing with erosion problems, need to level a slope, or want to create something beautiful on your Methuen, Andover, or Haverhill property, these walls offer compelling advantages. They handle our New England freeze-thaw cycles like champs, work with your landscape instead of fighting it, and won’t crack when the ground shifts.

Getting started means taking a good look at your site first. What kind of soil do you have? How’s the drainage? What’s your vision for the space in five or ten years? These questions matter because this system grows with your landscape.

Budget-wise, you’ve got options. Smaller projects under 4 feet can be great DIY projects if you’re handy and have the time. For bigger walls or tricky sites, bringing in professionals makes sense – especially when you factor in permits and engineering requirements.

The sustainability angle is hard to ignore. Cut your carbon footprint in half compared to concrete. Filter stormwater naturally. Create habitat for birds and beneficial insects. These aren’t just nice-to-haves anymore – they’re smart property investments.

At Dube Property Maintenance & Hardscaping, we’ve seen how these systems transform properties throughout Massachusetts and New Hampshire. Whether you’re tackling a small backyard slope or planning a major landscape renovation, we can help you figure out if a geotextile bag retaining wall makes sense for your situation.

Our team handles everything from the initial site evaluation through final planting and beyond. We know the local soils, understand the permit process, and have the experience to build walls that will still be beautiful and functional decades from now.

Ready to explore what’s possible for your property? Let’s talk about how these innovative walls can solve your challenges while creating something truly special in your landscape.

More info about retaining wall services